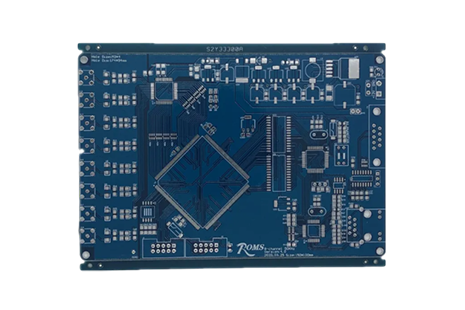

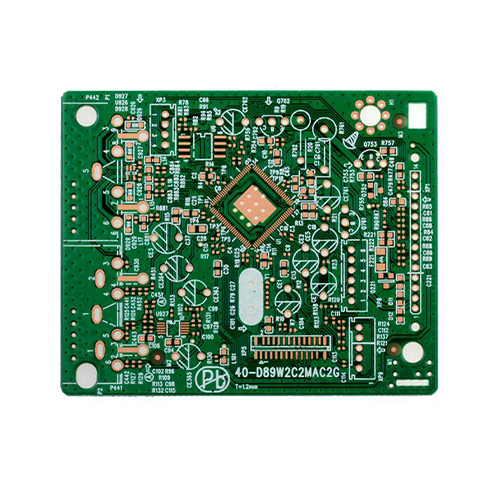

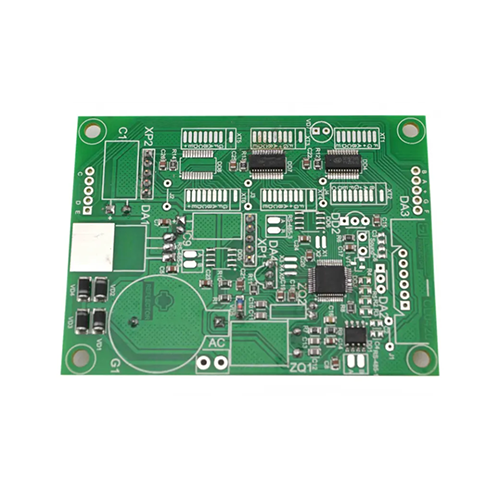

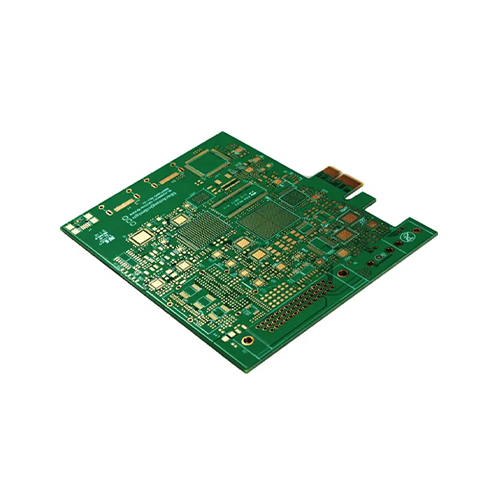

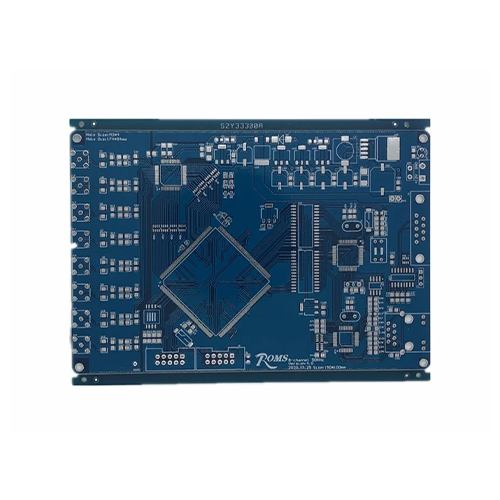

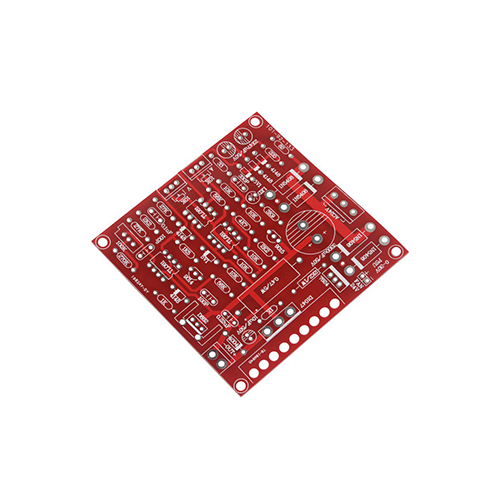

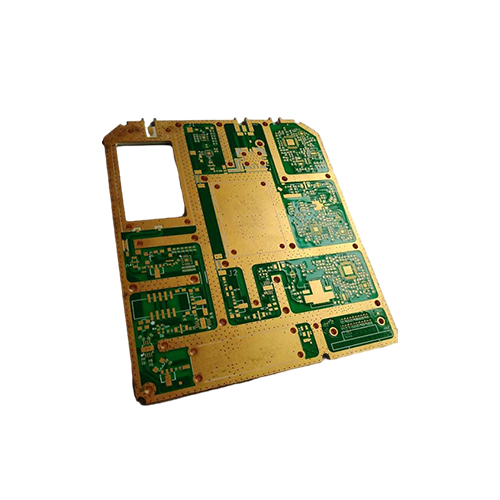

QukoPCB offers top-quality PCB assembly with no set-up fees and no stencil charges, providing a cost-effective solution. Using the latest YAMAHA PCB assembly equipment, we ensure precision, reliability, and exceptional results. Trust QukoPCB for streamlined assembly services made in China.

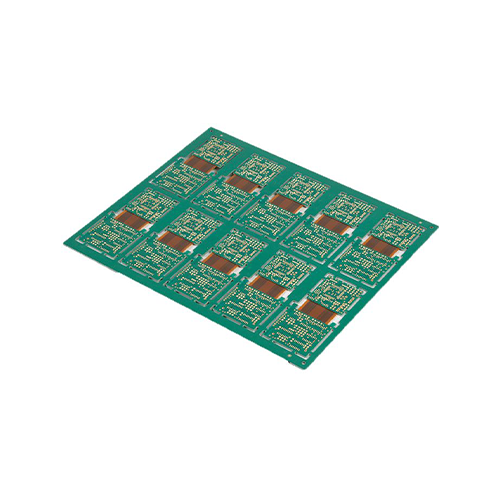

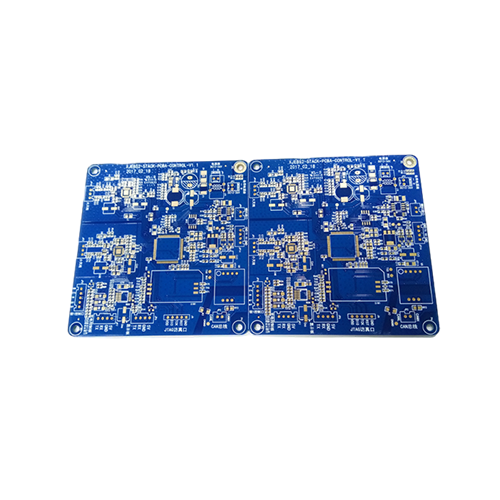

Our PCB assembly service offers a reliable turnkey solution in China, combining PCB fabrication and assembly under one roof. We specialize in small to medium production runs with fast lead times and no minimum order requirements.

Our turnkey PCB assembly service includes comprehensive component sourcing, ensuring a seamless production process. We provide 24-hour BOM quotes, 60,000+ in-stock components from 3,000+ brands, and access to 20 million parts from top suppliers like DigiKey and Mouser, ensuring fast, reliable sourcing and streamlined assembly.

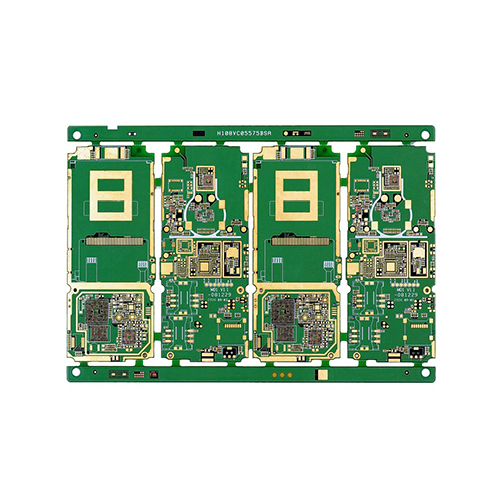

QukoPCB operates a state-of-the-art PCBA factory with 10 SMT lines in Shenzhen, China. Unlike brokers, we directly manage our production, ensuring strict quality control and competitive pricing.

Choose QukoPCB for precision, efficiency, and unmatched production capabilities.

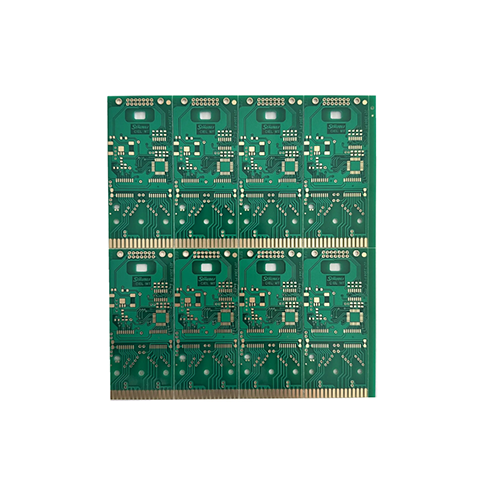

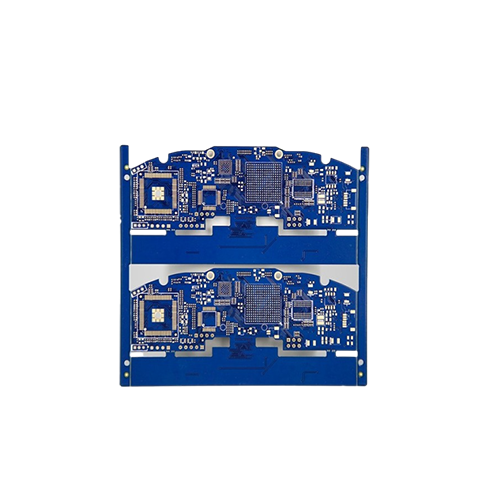

Specifications

Specs

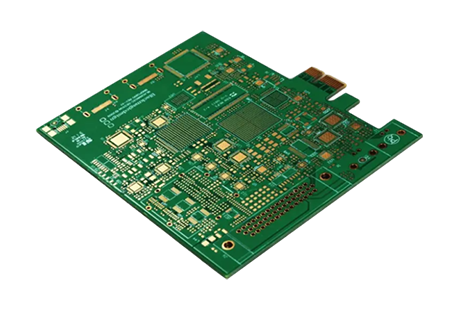

Assembly Types

Surface mount (SMT)

Through-hole (DIP)

Mixed technology (SMT & Thru-hole)

Ball-Grid-Array (BGA) Assembly

Mixed Assembly

(Single & double sided placement)

Lead Time

From 24 hours to 7 days once all parts are prepared.

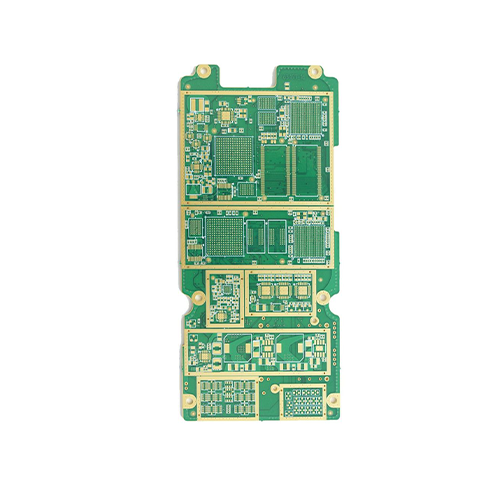

Quantity Req.

1~1000+

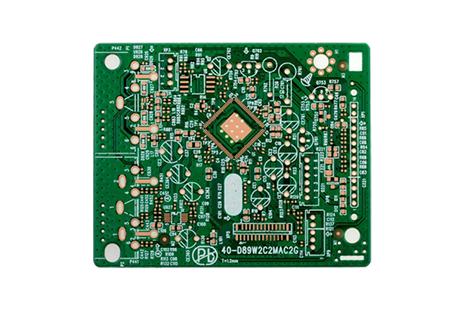

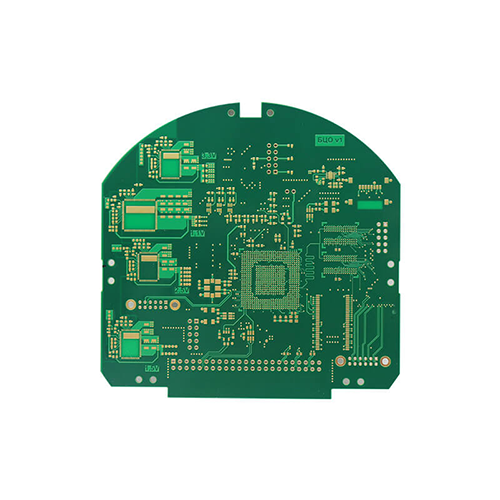

Board Type

Rigid PCB, Flexible PCB, metal core PCB

Component Sourcing

Turnkey (All components sourced by QukoPCB)

Partial turnkey

Kitted/Consigned

Cert. / Qualifications

IPC-A-610

Max. Board Size

500mm X 400mm

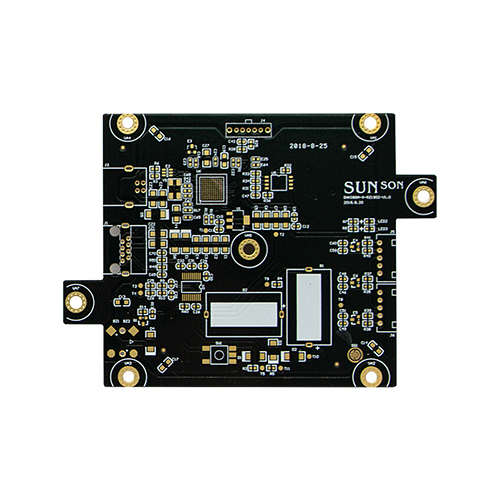

Surface Finish

Lead/Lead-free HASL (RoHS compliant), Immersion gold, OPS, etc.

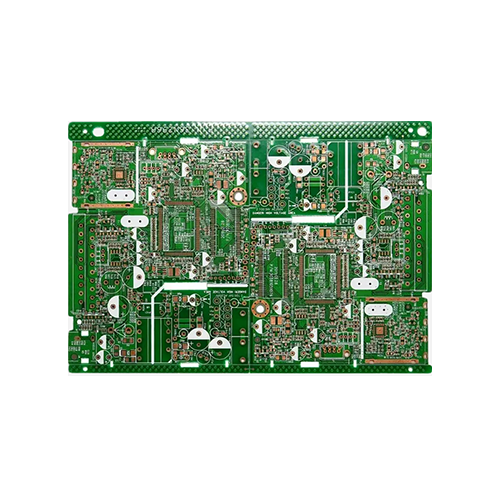

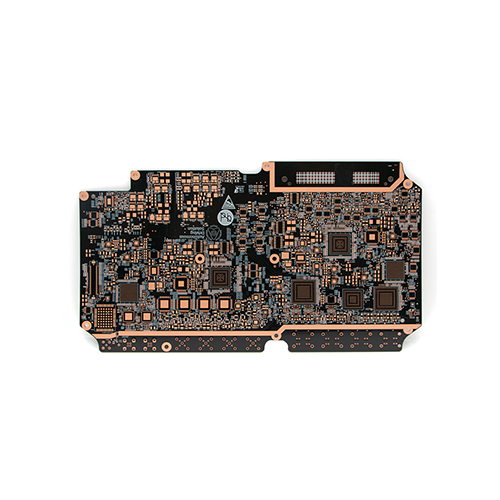

At QukoPCB, quality is at the core of our PCB assembly services. With our state-of-the-art facility and 10 SMT lines, we adhere to ISO 9001:2005 standards to ensure consistent quality and precision in every project. Our process includes thorough inspections, automated optical inspection (AOI), and functional testing, all designed to deliver reliable, high-performance PCB assemblies.

Electrical Test (E-test)

We perform electrical testing to verify the integrity and functionality of the PCB, ensuring that all connections and circuits are working as designed.

Functional testing

Before shipping we will check if the assembled PCB works as it should, making sure all parts are functioning properly and the board does what it's supposed to do.

X-ray Inspection

We uses X-rays to look inside the assembled PCB to find hidden issues like poor soldering or misaligned components that can't be seen with the naked eye.

Automated Optical Inspection (AOI)

AOI technology is used to automatically scan the assembled PCB for defects in solder joints, component placement, and traces, providing an additional layer of quality assurance.

Choose QukoPCB for your assembly needs, and experience quality you can trust.

Please leave your message below and we will contact you within 6 hours.

© 2025 QukoPCB, All Rights Reserved