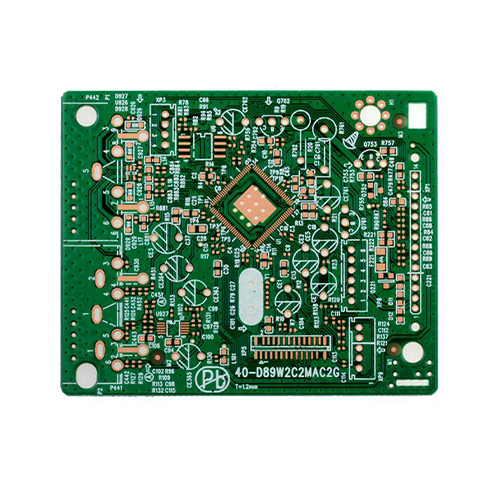

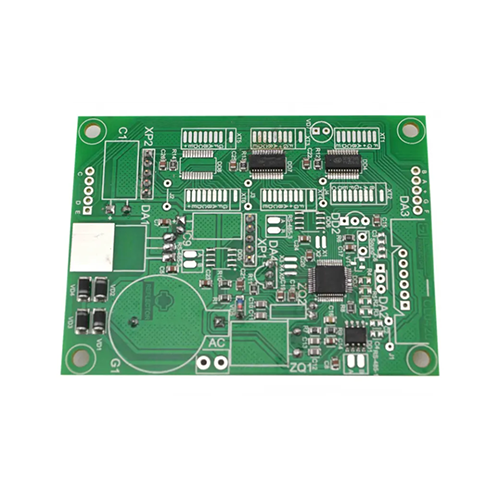

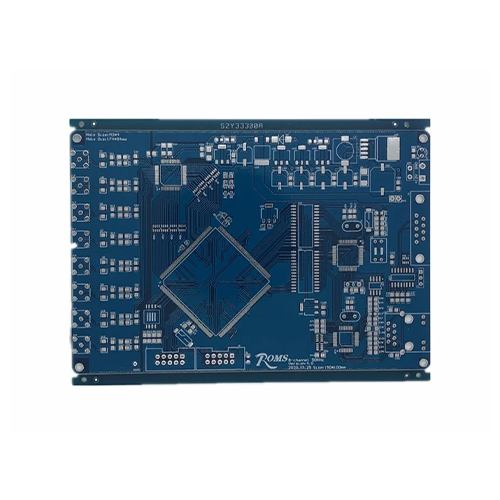

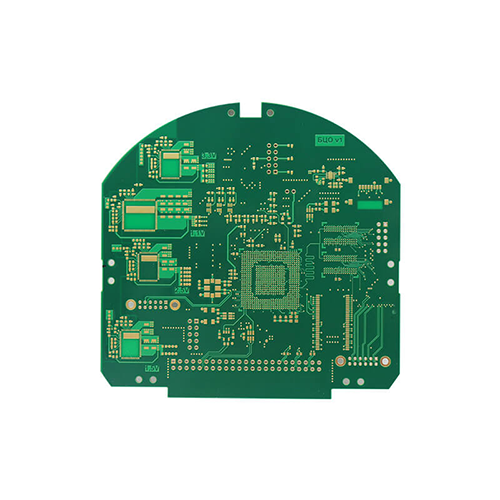

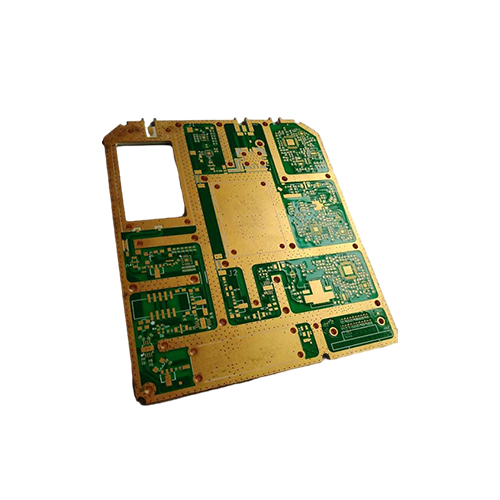

QukoPCB offers rapid-turn PCB prototype services at competitive prices. We deliver high-quality PCBs manufactured in China. Choose QukoPCB for your prototype needs and experience excellence in every step.

At QukoPCB, we stand by the quality of our products. If you encounter any quality issues, you can return the PCB and receive a full refund within 30 days of purchase. Your satisfaction is our priority, and we are committed to ensuring you receive the best products and service.

For corporate clients, your first order can be FREE for PCB costs up to $100. We are committed to building long-term partnerships with our clients. Contact us today to see how we can serve your needs.

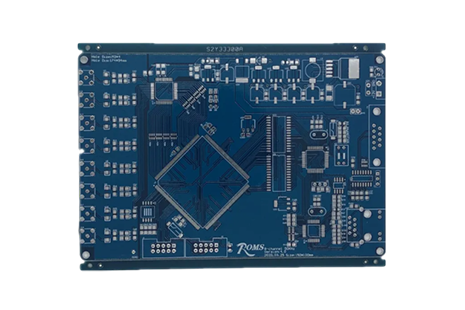

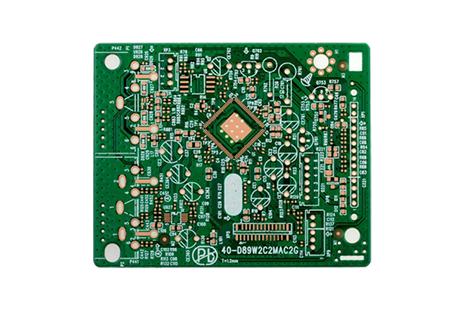

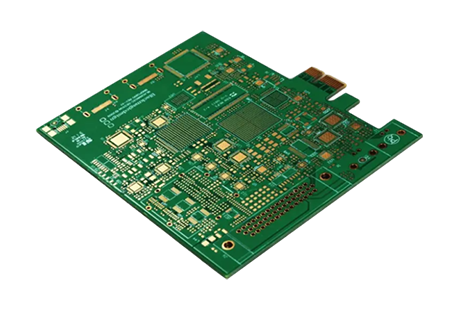

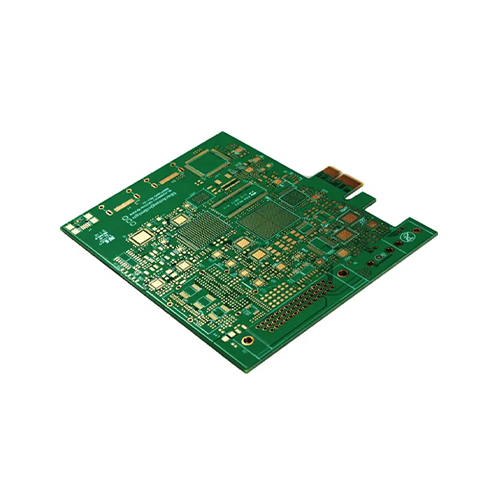

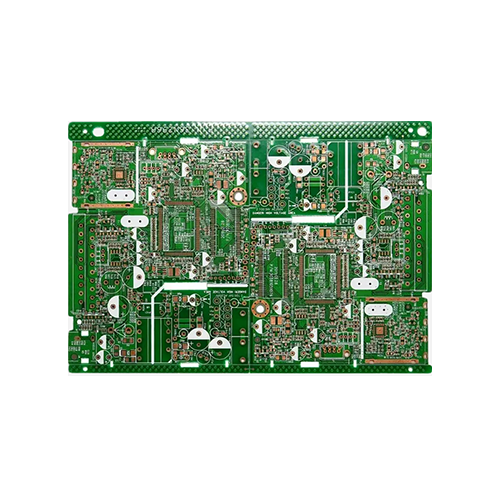

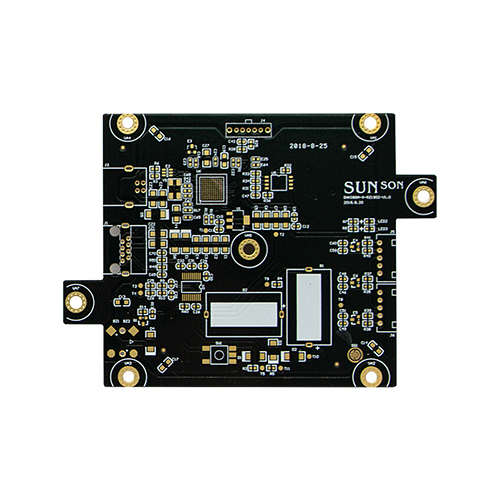

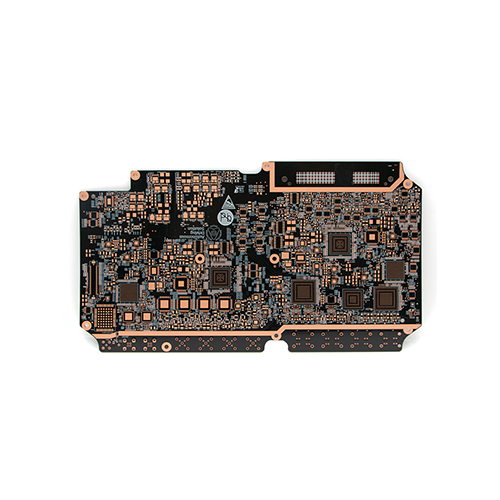

At QukoPCB, quality is our top priority. We support IPC Class 3 standards (IPC-A-610 and IPC-A-620) to ensure exceptional reliability and performance of PCBs. Our factories comply with ISO 9001:2005 and IATF 16949 standards, reflecting our commitment to excellence. Every PCB we manufacture undergoes rigorous testing and quality control processes. We are proud to have earned UL, REACH, and RoHS certifications, demonstrating our dedication to meeting global safety and environmental standards. We ensure that our customers receive products they can trust.

At QukoPCB, we stand by the quality of our products. If you encounter any quality issues, you can return the PCB and receive a full refund within 30 days of purchase. Your satisfaction is our priority, and we are committed to ensuring you receive the best products and service.

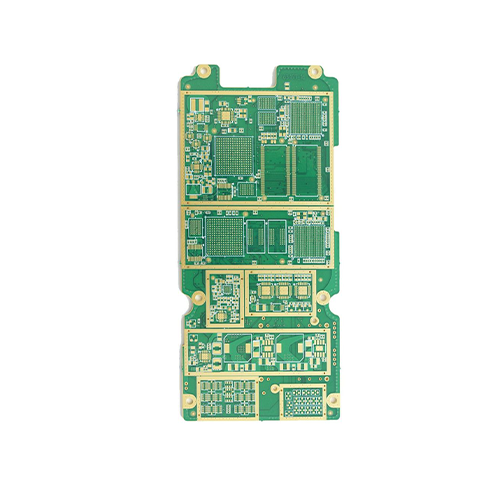

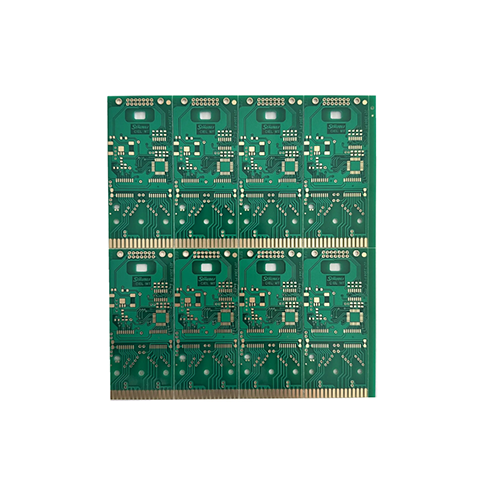

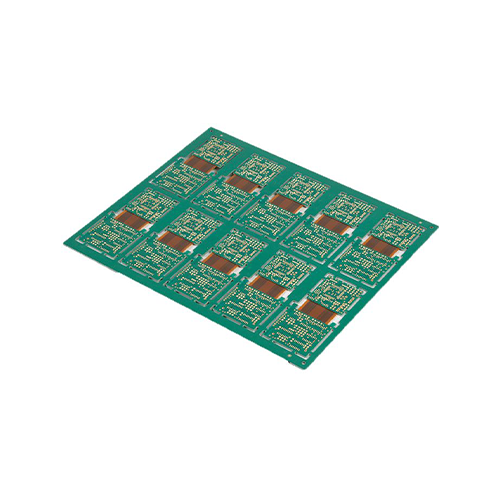

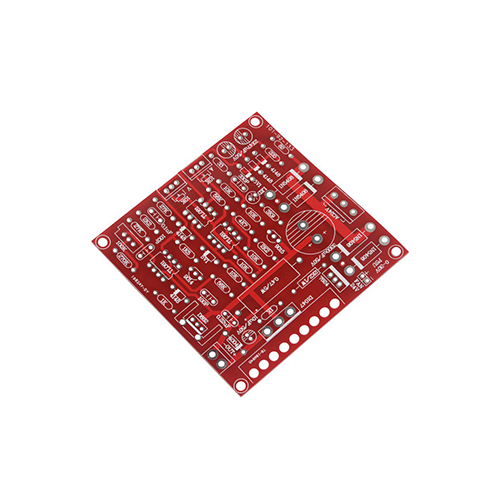

Specifications

Specs

Layer Count

1~32 Layers

Turn Time

Same Day 5 week

Quantity Req.

1~1000+

Materials

FR-4 /Aluminum/ Copper core/ Rogers PTFE Teflon/ CEM-1/ CEM-3/ Polyimide

Plate Finish

HASL lead-free, HASL with lead ENIG, OSP HardGold, ENEPIG, Immersion silver(Ag) Immersion tin

Cert. / Qualifications

IPC Class 3

Board Thickness

0.2/0.4/0.6/0.8/1.0/1.2/1.6/2.0/2.5/3.0/3.2mm

Copper Weight

0.5 oz. Inner / Up to 2 oz. Outer

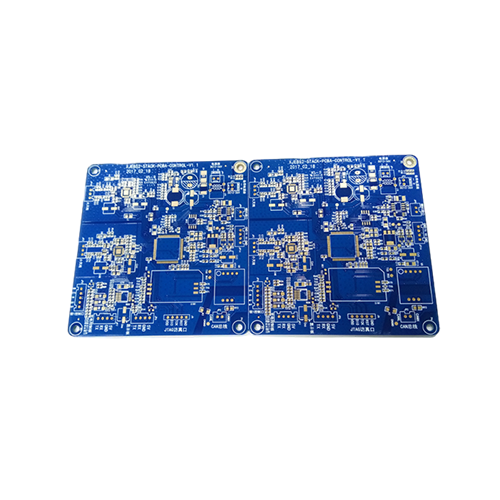

At QukoPCB, we put significant effort into ensuring the highest quality for every PCB we manufacture. Each PCB board undergoes comprehensive testing before it is shipped to our customers. Our rigorous testing process includes: ISO 9001:2005 Test report support

Electrical Test (E-test)

We perform electrical testing to verify the integrity and functionality of the PCB, ensuring that all connections and circuits are working as designed.

Flying Probe Test

This non-contact testing method allows us to check for open circuits, shorts, and other faults without the need for a custom test fixture, making it ideal for prototypes and

low-volume production.

Special Test Fixture

For high-volume orders or complex designs, we use custom test fixtures to conduct precise and efficient testing, ensuring consistent quality across all units.

Visual Inspection

Every PCB is visually inspected to identify any surface defects, such as scratches, soldering issues, or misalignments, ensuring the physical quality meets our strict standards.

Automated Optical Inspection (AOI)

AOI technology is used to automatically scan the PCB for defects in solder joints, component placement, and traces, providing an additional layer of quality assurance.

Through these meticulous testing procedures, we guarantee that every PCB leaving our facility meets our stringent quality standards, providing you with reliable and high-performing products. ISO 9001:2005 Test report support

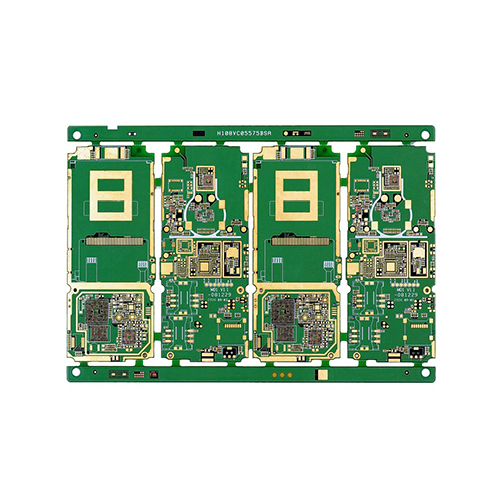

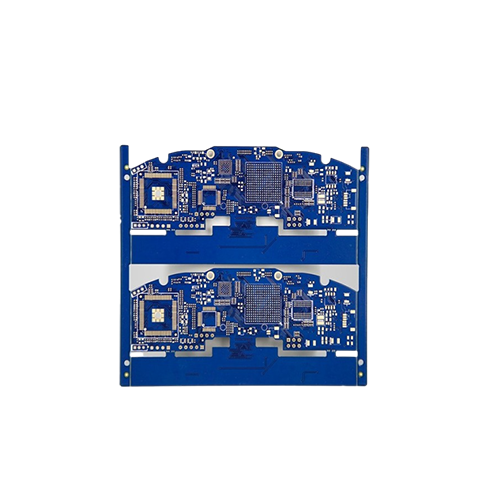

Engineers at the around world choose QukoPCB for the highest quality rigid PCB manufacturing and assembly. With our expertise and commitment to excellence, we help you bring your ideas to life.

Please leave your message below and we will contact you within 6 hours.

© 2025 QukoPCB, All Rights Reserved